Your first-choice precision sheet metal manufacturer

Based in Gloucester, with over 40 years of experience, we specialise in prototype, small and large batch precision sheet metal fabrications that cover a diverse range of products, from safe electronic enclosures to aerospace components.

Working closely with our clients to develop their ideas, we provide a complete sheet metal work solution with a “one-stop-shop” approach, handling every manufacturing stage under one roof, taking the stress out of your procurement.Fabrication

-

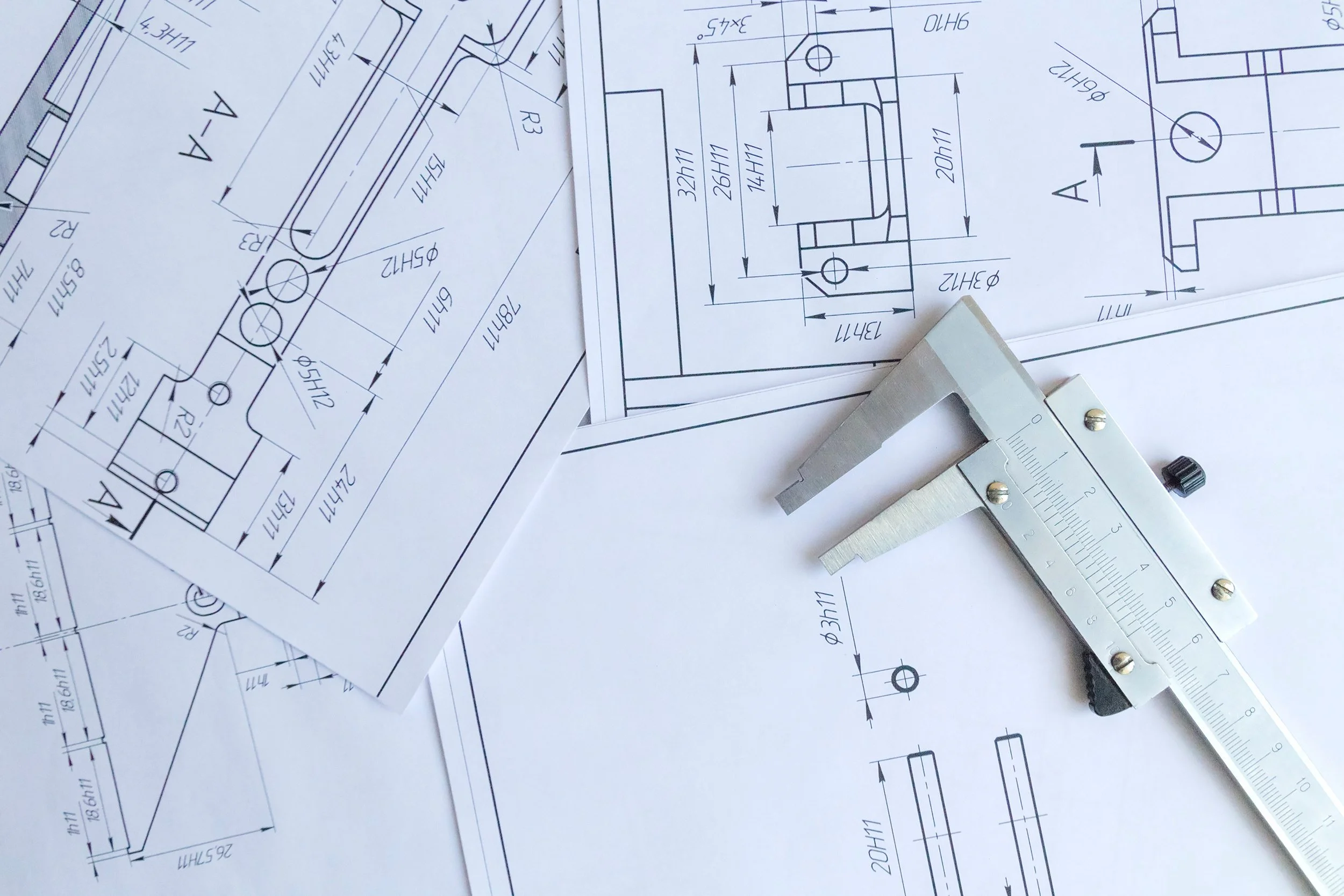

✔ CAD/CAM Design

We offer expert CAD/CAM support using Solidworks and the latest software to deliver precise design and manufacturing solutions.

-

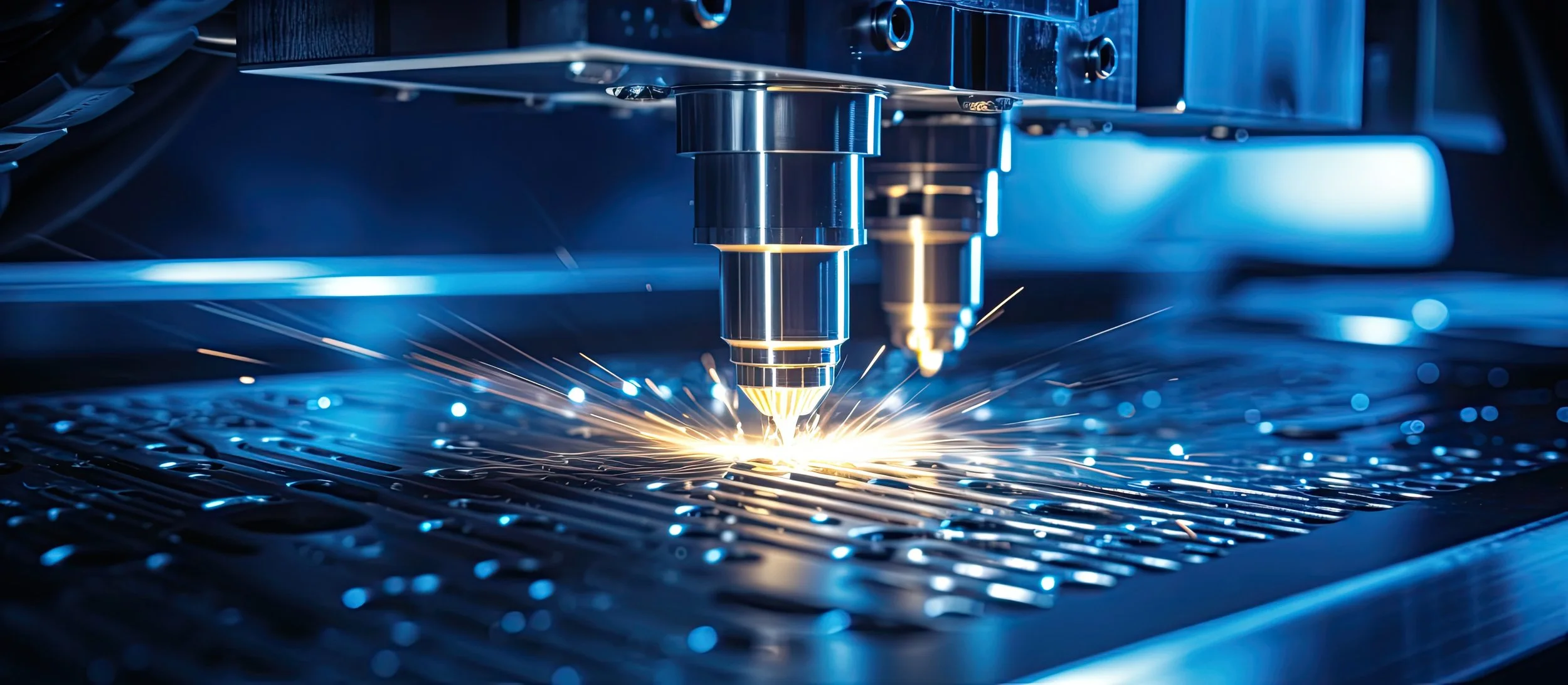

✔ Laser Cutting

Advanced laser cutting of steel, aluminum, and stainless steel ranging from 0.5-10mm thickness, performed on our 3m x 1.5m laser cutters.

-

✔ CNC Punching

Equipped with high-performance punch presses, Formrite provides precise, repeatable punching and forming for specific requirements.

-

✔ Folding and Forming

Formrite’s highly skilled team delivers precision forming on multi-axis press brakes, handling lengths up to 2.5metres with expert accuracy.

-

✔ Welding

High-quality precision TIG and laser welding for components covering various industries. Fettling and grinding to allow for a smooth finish.

-

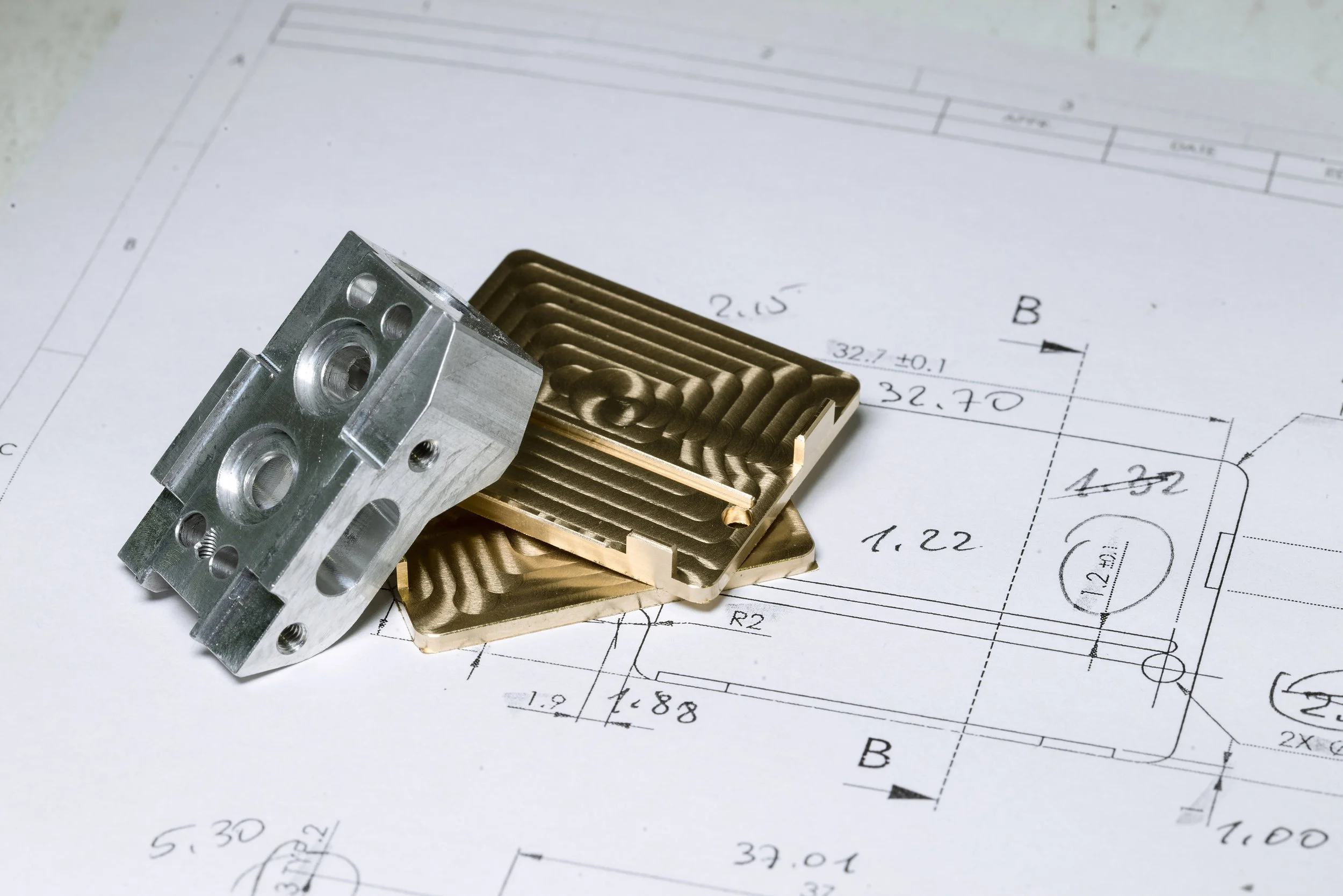

✔ CNC Machining Turning

Multi axis CNC machine with the latest CAD/CAM software, enabling seamless integration for all your procurement needs.

-

✔ Threaded Inserting

With our pneumatic press, Formrite installs metal studs with controlled force and accuracy ideal for secure mechanical fastening.

-

✔ Volume Production

We offer efficient volume production to help reduce your unit costs, with flexible scheduling, while ensuring consistent quality across every order.

Finishing Services

-

✔ Pre-treat and Plating

Our in-house processes, Surtec 650 and Alocrom 1200, seal aluminium to prevent oxidation and provide an etch for a more durable paint finish.

-

✔ Powder Coating

Our fully equipped in-house powder coating facility ensures exceptional quality and reliable service, delivering a hard-wearing, professional finish.

-

✔ Wet Spray

Our dedicated in-house wet spray facility enables the best quality and service, delivering uniform results with a smooth, consistent coverage.

-

✔ Silk Screen Printing

Formrite’s in-house silk screen printing service completes our ability to provide a one-stop shop for single-source procurement.

-

✔ Laser Etching

We offer laser etching, a high-resolution alternative when screen printing isn’t feasible; perfect for logos, barcodes, and serial numbers.

-

✔ Vinyl Labelling

Formrite offers durable, high-quality vinyl labels; a cost-effective and flexible alternative to laser etching, ideal for logos and barcodes.

-

✔ Component Assembly

We can prepare your components for final assembly, reducing your material handling and excess in-house production space and labour.

-

✔ Storing components

Formrite can store your components on-site, enabling bulk ordering and flexible, on-demand delivery to suit your production schedule.

“I am proud of the reputation that Formrite has built within the precision engineering industry over the last 40 years. We offer an honest, personal level of service, and I’m committed to supporting your projects. We are proud of our premises and machinery and I'd would be delighted to show you around. I look forward to hearing from you.”Gary Fairs,

Managing Director, Formrite Limited

What our customers think

"We have been using Formrite as a supplier for 10 years now and have always found them to produce high-quality work. They have made a wide-ranging variety of products for us in aluminium, mild and stainless steel and also powder coating where required is first class, we would have no reservations in recommending them."— Andy Freeman,

Managing Director at Cadfan Ltd.

“We have been partnering with Formrite for many years, and the services they provide have consistently exceeded our expectations. Their expertise is evident in the high-quality parts that they deliver, on time and within budget. We would highly recommend Formrite to any company seeking a reliable, top-notch service.”— Andy Woodward,

Purchasing Manager in Computer Security

“A professional, proactive, forward-thinking company who adapt to our business needs. Always willing to try new ideas, with a positive “can-do” attitude. Gary is always flexible and accommodating, providing support and consistency which makes working together straightforward and stress-free."